大冶市都鑫摩擦粉体有限公司

Duxin Friction Powder of Daye Co., Ltd

大冶市都鑫摩擦粉体有限公司成立于2002年,是湖北大冶的一家专业科研、生产、销售、服务为一体的摩擦粉体材料供货基地。我公司充分依托当地优势资源,以高新技术、精密设备为基础,将原始初级的矿产品,经过技术提纯、改进、改性等手段提升为高技术含量新型产品。公司为国家高新技术企业,现有发明专利8项,实用新型专利12项。

公司总投资达5000余万元,占地面积21000余平方米。我公司现配有大型生产机械设备7组,其他配套性设备15套,硫化锑专用生产线设备一套。

随着汽车刹车制动、军用摩擦、飞机火车闸瓦和砂轮制造等行业的兴起,市场要求的不断提升,我们公司不断适应市场需求,主要为行业提供增摩、减摩、润滑等精良摩擦原材料和优质的人性化服务。通过我们提供的原料,为制动行业制造出安全、环保、耐用的摩擦制品。我公司先后为东风、奥迪等刹车片配套生产商提供专用摩擦原材料,零售供应客户数达三百多家,出口产品销至马来西亚、美国、南美等国际知名企业。

主营产品:硫化锑、铬铁矿、二硫化钼、人造颗粒石墨等粉末原材料.

在未来的三年内,我们计划在我司先进原材料的基础上,结合刹车片生产技术,向汽车刹车片行业挺进,逐步将公司转型为一条龙式生产链的技术型汽车制动服务企业。

DUXIN FRICTION POWDER OF DAYE CO.,LTD was established in 2002, is a professional research, production, sales, service as one of the friction powder material supply base. Our company fully relies on the local advantageous resources, takes the high-tech, the precision equipment as the foundation, promotes the original primary mineral product, through the technical purification, the improvement, the modification means to the high-tech content new product. The company is a national high-tech enterprise, with 8 invention patents and 12 utility model patents.

The total investment of the company is more than 50 million RMB, covering an area of 21000 square meters. Our company is equipped with 7 sets of large-scale production machinery and equipment, 15 sets of other supporting equipment, and a set of special production line equipment for antimony sulfide.

With the rise of automobile brake, military friction, aircraft and train brake shoe and grinding wheel manufacturing industry, and the continuous improvement of market requirements, our company constantly adapts to the market demand, mainly providing excellent friction raw materials such as friction increase, friction reduction, lubrication and other high-quality humanized services for the industry. Through the raw materials we provide, we can produce safe, environmentally friendly and durable friction products for the brake industry. Our company has successively provided special friction raw materials for Dongfeng, Audi and other brake pad manufacturers, with more than 300 retail customers, and exported products to Malaysia, the United States, South America and other international well-known enterprises.

Main products: antimony sulfide, chromite, molybdenum disulfide, artificial granular graphite, other powder raw materials

In the next three years, based on our advanced raw materials, combined with brake pad production technology, we plan to advance to the automotive brake pad industry, and gradually transform the company into a one-stop production chain technology-based automobile brake service enterprise.

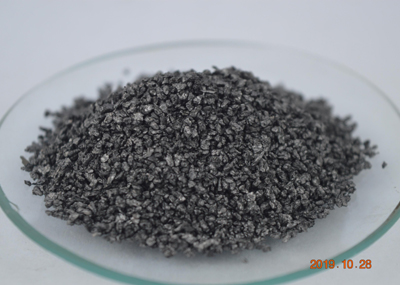

硫化锑

黑色或灰黑色粉末,斜方晶体结构。硫化锑是由辉锑矿经过精选和化学提纯而得,为黑色固体粉末。它的熔点比较低,为548℃,高温分解后生成的氧化锑,以及在还原剂存在时生成的金属锑,主要性能:

1、能防止高温时材料的氧化燃烧,保持材料的摩擦稳定性,提高材料的抗烧性能;

2、还能降低有机粘合剂在高温时分解速度,提高材料的使用寿命,起到了高温无机粘合剂和润滑摩擦调整剂的作用。

3、此外硫化锑以及在制动过程中高温反应的硬度都比较低,可以减少摩擦材料制动时产生的噪音和震动。

4、硫化锑具有突出的调节摩擦系数的性能,200℃以下低温润滑,250℃高温稳定摩擦系数,抗衰退。

5、并且国内外有的盘式配方中,发现硫化锑的使用可以起到高温无机粘结剂的作用,从而减少树脂用量。

6、我公司生产的硫化锑粒度为1600目超细粒度,能增加产品流动性,提高产品比表面积,使用更充分。

Antimony sulfide

Black or grayish black powder with rhombic crystal structure. Antimony sulfide is a black solid powder obtained from stibnite after cleaning and chemical purification. Its melting point is relatively low, which is 548 ℃. The antimony oxide formed after high temperature decomposition and the metal antimony generated in the presence of reducing agent are as follows

1. It can prevent the oxidation and combustion of the material at high temperature, maintain the friction stability of the material, and improve the burning resistance of the material;

2. It can also reduce the decomposition speed of organic adhesive at high temperature, improve the service life of the material, and play the role of high temperature inorganic adhesive and lubricating friction regulator.

3. In addition, the hardness of antimony sulfide and high temperature reaction during braking is relatively low, which can reduce the noise and vibration of friction materials during braking.

4. Antimony sulfide has outstanding performance of adjusting friction coefficient, lubricating at low temperature below 200 ℃, stable friction coefficient at high temperature at 250 ℃, and anti degradation.

5.It is found that the use of antimony sulfide can play an important role in high temperature inorganic binder, thus reducing the amount of resin.

6. The particle size of antimony sulfide produced by our company is 1600 mesh, which can increase the fluidity and specific surface area of the product and make it more fully used.

人造石墨

我公司生产的是采用进口电极碳素、优质低灰煅烧石油焦碳为原料,经3000℃以上连续8-10小时真空高温石墨化热处理而制成。该产品具有以下特点:

(1)石墨化程度高,结晶细密。

(2)含碳量高,挥发份少,物理化学性质十分稳定。

(3)硬度低、气孔率大、导热系数低。

(4)产品达到超过国外进口产品的技术指标

该产品用于摩擦材料中可明显提高粘接性、稳定摩擦系数、维持制动过程平稳、舒适,降低对偶表面损伤及制动噪音、降低磨损率。

Our company adopts imported electrode carbon and high quality low ash calcined petroleum coke as raw materials, and is made by vacuum high temperature graphitization heat treatment above 3000 ℃ for 8-10 hours. The product has the following characteristics:

(1) High degree of graphitization and fine crystal.

(2) High carbon content, less volatile, physical and chemical properties are very stable.

(3) Low hardness, high porosity and low thermal conductivity.

(4) The product has reached the technical index of imported products

The product can obviously improve the adhesion, stabilize the friction coefficient, maintain the smooth and comfortable braking process, reduce the dual surface damage and braking noise, and reduce the wear rate.

铬铁矿

铬铁矿粉具有较好的低温和高温增摩效果,也能起到清扫对偶的作用。细粒度的铬铁矿添加于刹车片中能起到很好的增摩作用,而不刮伤对偶和产生噪音。在摩擦材料中常用的铬铁矿粉的cr203,含量为25%-45%,cr203含量越高,增摩效果也越大。使用时应注意控制其用量和粒径。合宜的用量应不超过7%,粒径细度在325目以上。过多的用量和过粗的粒径固然能提高摩擦系数但也会导致摩损明显增大。

Chromite powder has good friction increasing effect at low temperature and high temperature, and can also play a dual role in cleaning. The addition of fine-grained chromite to the brake pad can increase the friction without scratching and noise. The content of Cr203 in chromite powder is 25% - 45%. The higher the content of Cr203, the greater the friction effect. The dosage and particle size should be controlled. The suitable dosage should not exceed 7%, and the particle size and fineness should be above 325 mesh. Excessive amount and coarse particle size can improve the friction coefficient, but also lead to the obvious increase of friction loss.