梁山诚通摩擦材料有限公司

Liangshan Chengtong friction material Co., Ltd

梁山诚通摩擦材料有限公司,位于著名的水泊梁山遗迹-东平湖畔,是专注喷胶岩棉的生产、销售的企业。多年来在认真学习发达国家的先进技术、先进工艺、先进经验的基础上,刻苦钻研,大胆实践,不断创新,生产的喷胶岩棉纤维,广泛应于无石棉摩擦材料的盘刹车片、鼓式刹车片、离合器面片、摩托车用材料和工程机械材料,同时也用于无石棉密封材料。这些材料的应用对提高摩擦材料的安全性、舒适性、耐磨性,降低制动噪音,减少环境污染,降低生产成本,提高经济效益起到了积极作用。

Liangshan Chengtong friction material Co., Ltd., located on the Bank of Dongping Lake, the famous Shuibo Liangshan relic, is an enterprise focusing on the production and sales of glue sprayed rock wool. Over the years, on the basis of conscientiously studying the advanced technology, advanced process and advanced experience of developed countries, we have studied hard, practiced boldly and made continuous innovation. The produced glue sprayed rock wool fiber is widely used in disc brake pads, drum brake pads, clutch face pads, motorcycle materials and engineering machinery materials of asbestos free friction materials, as well as asbestos free sealing materials. The application of these materials has played a positive role in improving the safety, comfort and wear resistance of friction materials, reducing braking noise, reducing environmental pollution, reducing production costs and improving economic benefits.

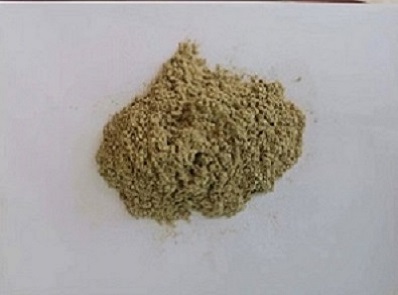

我公司生产的喷胶岩棉纤维是由玄武岩等矿物经过粉碎、高温熔化、吹丝、喷胶、短切、去除渣球等加工而成的短纤维、可用于无石棉摩擦材料,特别适用盘式刹车片和鼓式刹车片,它具有以下使用特点:

1、由于其价格便宜,能大幅度的降低摩擦材料的制造成本。

2、渣球含量低,与玻璃纤维和硅石灰相比,产品硬度低能降低摩擦材料的噪音和振动。由于表面涂胶,提高了摩擦材料的耐磨性。

3、由于岩棉有比较低的熔化温度,因此,在高温时比较软,因此可以减少对偶的磨损和起到高温辅助黏合剂的作用,它附于摩擦材料表面能有效降低摩擦材料中其他低温材料的热衰退性和膨胀性,提高了摩擦材料在制造和使用过程中的稳定性,是石棉摩擦材料的重要代用纤维。

4. 有较强的吸附性,可吸附各种粉状材料,使摩擦材料巩固性增强;易分散,刺激皮肤粉尘少,对人体健康无害。

The glue sprayed rock wool fiber produced by our company is a short fiber made of basalt and other minerals through crushing, high-temperature melting, blowing, glue spraying, short cutting, slag ball removal and other processing. It can be used for asbestos free friction materials, especially suitable for disc brake pads and drum brake pads. It has the following use characteristics:

1. Because of its low price, it can greatly reduce the manufacturing cost of friction materials.

2. The slag ball content is low. Compared with glass fiber and silica lime, the hardness of the product is low, which can reduce the noise and vibration of friction materials. Because the surface is coated with glue, the wear resistance of friction materials is improved.

3. Because the rock wool has a relatively low melting temperature, it is relatively soft at high temperature, so it can reduce the dual wear and play the role of high-temperature auxiliary adhesive. Its attachment to the friction material surface can effectively reduce the heat recession and expansion of other low-temperature materials in the friction material, improve the stability of the friction material in the manufacturing and use process, and is an important substitute fiber of asbestos friction material.

4. It has strong adsorption and can adsorb all kinds of powdery materials to enhance the consolidation of friction materials; Easy to disperse, less dust irritating the skin, and harmless to human health.