陵县嘉诚工贸有限公司

Lingxian Jiacheng industry and trade Co., LTD

陵县嘉诚工贸有限公司位于山东省德州市陵城区宋家镇开发区。是一家集资本,产业结构多元化企业、常年与国内多家汽车主机厂配套合作。

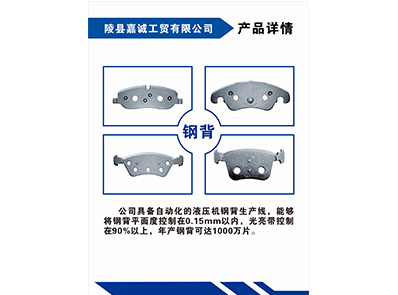

公司已通过1S09001、和QS9000、S0/TS16949等认证。公司主要生产汽车盘式刹车片钢背、重型刹车蹄。产品加工采用OEM工艺,具备自动化的液压机钢背生产线,可实现冲压、焊接、铣削、整形等工艺的一体化加工。能够将钢背平面度控制在0.15mm以内,光亮带控制在90%以上。产品钢背关键性指标完全达到了国内OE配套市场的标准。

公司开发团队能独立完成新产品整套模具的设计、制造工作。公司通过高效的研发团队、先进的设备、现代化的企业管理系统确保向客户提供优质的产品和一流的服务。

Lingxian Jiacheng Industry and Trade Co., Ltd. is located in Songjia Town Development Zone, Lingcheng District, Dezhou City, Shandong Province. Is a collection of capital, industrial structure of diversified enterprises, perennial with a number of domestic auto Oems supporting cooperation.

The company has passed 1S09001, QS9000, S0/TS16949 and other certifications. The company mainly produces automobile disc brake pads steel back, heavy brake shoes. Product processing using OEM technology, with automatic hydraulic steel back production line, can achieve stamping, welding, milling, shaping and other processes integrated processing. The flatness of the steel back can be controlled within 0.15mm, and the bright belt can be controlled above 90%. The key indicators of steel back products have fully reached the domestic OE supporting market standards.

The development team of the company can independently complete the design and manufacturing of the whole set of new products. The company through efficient R & D team, advanced equipment, modern enterprise management system to ensure to provide customers with quality products and first-class service.

公司具备自动化的液压机钢背生产线,能够将钢背平面度控制在0.15mm以内,光亮带控制在90%以上,年产钢背可达1000万套。

产品采用优质的钢材作为原材料,对其化学成分和机械性能参数都有严格要求。采用全自动流水线生产:压斜边-冲孔-压钉-整平-去毛刺一次成型,过程全部实现自动化生产,效率更高、工艺更精湛,力求产品每个细节接近完美。钢背的尺寸、厚度、孔的尺寸,严格按照图纸要求检验,检验数据直接生成检验报告。公司的模具都是使用优质模具材料经过精密加工而来,每年新增500多个产品型号,能够为客户提供定制化服务;公司采用标准化的模具开发理念,保证产品的一致性。公司的钢背在冲压过程中,为了提升钢背的平面度和光亮度,会采用一段时间的保压,来保证每一片产品的质量,这样公司生产的钢背不仅能够降低刹车片生产过程中的分层裂纹,而且能够降低刹车噪音,使刹车更加顺畅。

The company has an automated hydraulic steel back production line, which can control the flatness of the steel back within 0.15mm, control the bright belt above 90%, and the annual production of steel back can reach 10 million sets.

The product uses high-quality steel as raw materials, and has strict requirements on its chemical composition and mechanical property parameters. The use of automatic production line: bevel pressing - punching - pressing nail - leveling - deburring molding, the process to achieve automatic production, higher efficiency, more exquisite technology, and strive to every detail of the product close to perfect. The size, thickness and hole size of the steel back shall be inspected in strict accordance with the requirements of the drawing, and the inspection report shall be generated directly from the inspection data. The company's molds are made of high-quality mold materials through precision machining, and more than 500 product models are added every year, which can provide customized services for customers; The company adopts standardized mold development concept to ensure product consistency. The company's steel back in the stamping process, in order to improve the flatness and brightness of the steel back, will be used for a period of time to maintain pressure, to ensure the quality of each piece of product, so that the company's steel back can not only reduce the delamination cracks in the production process of brake pads, but also reduce the brake noise, make the brake more smooth. The company has an automated hydraulic steel back production line, which can control the flatness of the steel back within 0.15mm, control the bright belt above 90%, and the annual production of steel back can reach 10 million sets.

The product uses high-quality steel as raw materials, and has strict requirements on its chemical composition and mechanical property parameters. The use of automatic production line: bevel pressing - punching - pressing nail - leveling - deburring molding, the process to achieve automatic production, higher efficiency, more exquisite technology, and strive to every detail of the product close to perfect. The size, thickness and hole size of the steel back shall be inspected in strict accordance with the requirements of the drawing, and the inspection report shall be generated directly from the inspection data. The company's molds are made of high-quality mold materials through precision machining, and more than 500 product models are added every year, which can provide customized services for customers; The company adopts standardized mold development concept to ensure product consistency. The company's steel back in the stamping process, in order to improve the flatness and brightness of the steel back, will be used for a period of time to maintain pressure, to ensure the quality of each piece of product, so that the company's steel back can not only reduce the delamination cracks in the production process of brake pads, but also reduce the brake noise, make the brake more smooth.