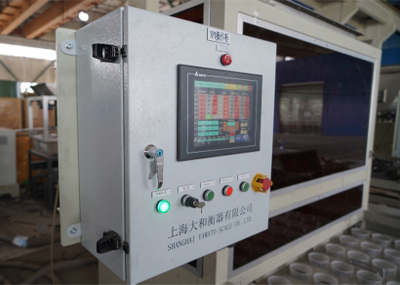

上海大和衡器有限公司

Shanghai Yamato Scale Co., Ltd

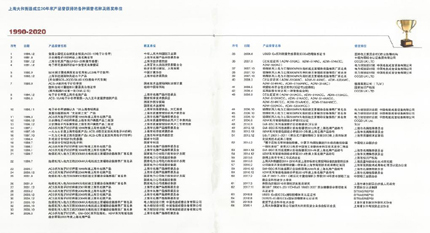

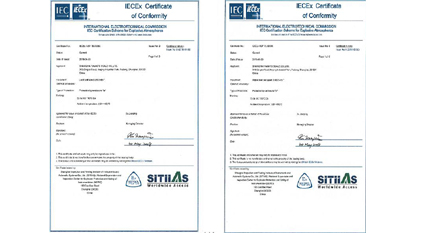

上海大和衡器有限公司总投资2000万美元,于1990年8月8日成立于浦东开发区。经过30年的不断发展,产品由普通小型衡器发展到工业大型衡器,产品获得上海市名牌产品的称号,是上海市高新技术企业、上海市专利工作试点企业。依托百年Yamato品牌,上海大和已成为中国衡器界屈指可数的品牌,在国内外汽车轮胎/零部件、钢铁、电力、水泥、食品、种子等行业享有很高的盛誉。

公司主要产品有自动工业用衡器及计量设备,产品涵盖轮胎配料及动/静平衡机,摩擦材料配料系统及自动称量机,RMC自动铆接系统和粉体自动配料系统。公司专业提供摩擦材料行业的计量及输送解决方案。

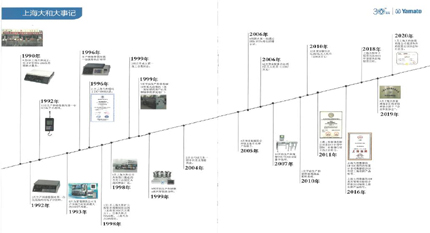

2020年正值日本大和成立100周年,也是上海大和成立30周年,我们将秉承创造、技术、信赖的宗旨,为客户提供先进的产品、优质的服务。上海大和将充分发挥衡器行业著名品牌的带头作用,进一步依靠日本大和领先的技术、遍布全球的网络,为海内外客户提供优质的服务。

Shanghai Yamato Scale Co., Ltd was established on 8th August 1990 with total investment reaching 20 million dollars. With 30 years’ development, our products transferred from the ordinary small-scale weighing equipment to the automatic and industrial large-scale weighing instrument. Our products have won the title of famous brand products in Shanghai, and are high-tech enterprises in Shanghai and pilot enterprises of Patent work in Shanghai. Based on centennial Yamato brand, Shanghai Yamato has become one of the most famous weighing equipment brands in China, enjoying high reputation in automobile tire/parts, steel, electric power, cement, food, seed and other industries at home and abroad.

Our main products are automatic industrial weighing equipment, which covering tire batching, dynamic/static balancing machine, friction material batching system and auto-weighing machine, RMC automatic riveting system and automatic powder batching system. We specializes in providing friction material industry measurement and delivery solutions

2020 is the 100th anniversary of Yamato of Japan and the 30th anniversary of Shanghai Yamato. We will adhere to the tenet of creation, technology and trust, and provide advanced products and high-quality services for customers. Shanghai Yamato will give full play to the leading role of well-known brands in the weighing equipment industry, and further rely on Japan's leading technology, worldwide network, to provide quality services to customers at home and abroad.

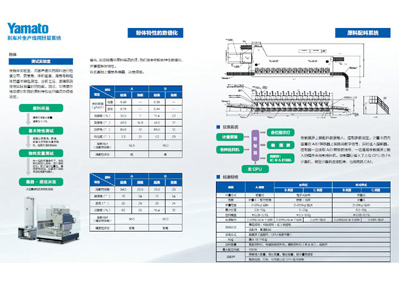

1)摩擦材料自动称量机

①采用日本大和原装进口称重基板和YAMATO品牌称重传感器,数据处理快速、称重精度高;

②具有单滚筒式、双滚筒式、管子式等多种喂料机构,可应对不同特性的物料;

③自动称量设备自带NG处理功能,此功能可由客户根据自身的生产需求,在操作屏上选择关闭或者启用;

④具备单联、双联、四联、六联等多个称量通道,以及单排、双排、三排等多排接料载台;也可以与用户压机联动,将称量好的物料直接送入压机模腔内。

2)RMC自动铆接系统

RMC自动铆接系统具有如下特点:

①自动送料、自动下料;不需要熟练工

②机器人自动抓取工件、自动铆接,定位精准,降低劳动强度

③采用气力输送形式自动供铆钉,有效避免铆接质量问题的发生

④操作人员远离铆接机工作区,大大降低危险

3)粉体自动配料系统

①上海大和拥有先进的粉体实验室,采用“全球性标准”的细川密克朗公司製的粉体测试仪对每种粉体原料进行料性分析,充分了解原料的密度、安息角、崩溃角、喷流性、流动性等关键指数,并据此建立粉体原料的数据库;在为客户设计选用设备前,会对客户原料进行测试并与数据库进行对比,依据测试数据科学的选择最适合的原料料仓和喂料形式,以此来保证系统运行的稳定性和配料精度的准确性;

②采用日本大和原装进口的称重仪表和YAMATO品牌称重单元,确保了自动配料过程的高速度和高精度;

③经过多年的技术积累,具有对自动配料系统中的各个分系统(原料的输送投料系统、原料自动称量系统、配合料的转运及混合系统、混合料的转运系统、除尘系统等)进行工艺设计、设备设计和控制软件设计的技术和生产能力。

1.Automatic friction material weighing machine

(1)Using Japan YAMATO original imported weighing board and YAMATO load cell achieves fast data processing and high weighing accuracy

(2)Features with single-drum, double-drum, pipe and other types of feeding mechanism, which can handle materials with different characteristics

(3)NG processing function which can be closed or enabled by the customer on the operation screen

(4)With single, double, four, six and other weighing channels, and single, double, three and multi row loading platform; It can also be linked with the user's press to directly feed the weighing material into the die cavity of the press

2.RMC automatic riveting system

Features:

(1)Automatic feeding, automatic cutting; No skilled workers are needed

(2)The robot automatically grabs the work piece, automatically riveting, accurate positioning, reduce labor intensity

(3)Adopt pneumatic conveying form to supply rivet automatically, effectively avoid the occurrence of rivet quality problem

(4)Operators away from the riveting machine work area, greatly reducing the risk

3.Automatic powder batching system

(1)Shanghai Yamato has an advanced powder laboratory, which uses the "global standard" powder tester made by Hosokawa Michikron Company to analyze the material properties of each powder raw material, so as to fully understand the density, resting Angle, collapse Angle, jet flow, fluidity and other key indexes of the raw material, and establish the database of powder raw materials accordingly; Before designing and selecting equipment for customers, the raw materials of customers will be tested and compared with the database. According to the test data, the most suitable raw material silo and feeding form will be scientifically selected to ensure the stability of system operation and the accuracy of batting accuracy

(2)Adopting weighing instruments and weighing units imported from Japan YAMATO to ensure high speed and precision of automatic batching process

(3)After years of technical accumulation, it has the technology and production capacity to design process, equipment and control software for each sub-system in the automatic batching system (raw material conveying and feeding system, raw material automatic weighing system, mixed material transferring system and dust removal system, etc.)